Picture 1 in fig 24 is for loose type flanges. Great info One thing I was looking for but did not find is the preferred way to pipe a tube shell heat exchanger I have a problem with 2 buildings connected with a central boiler plant.

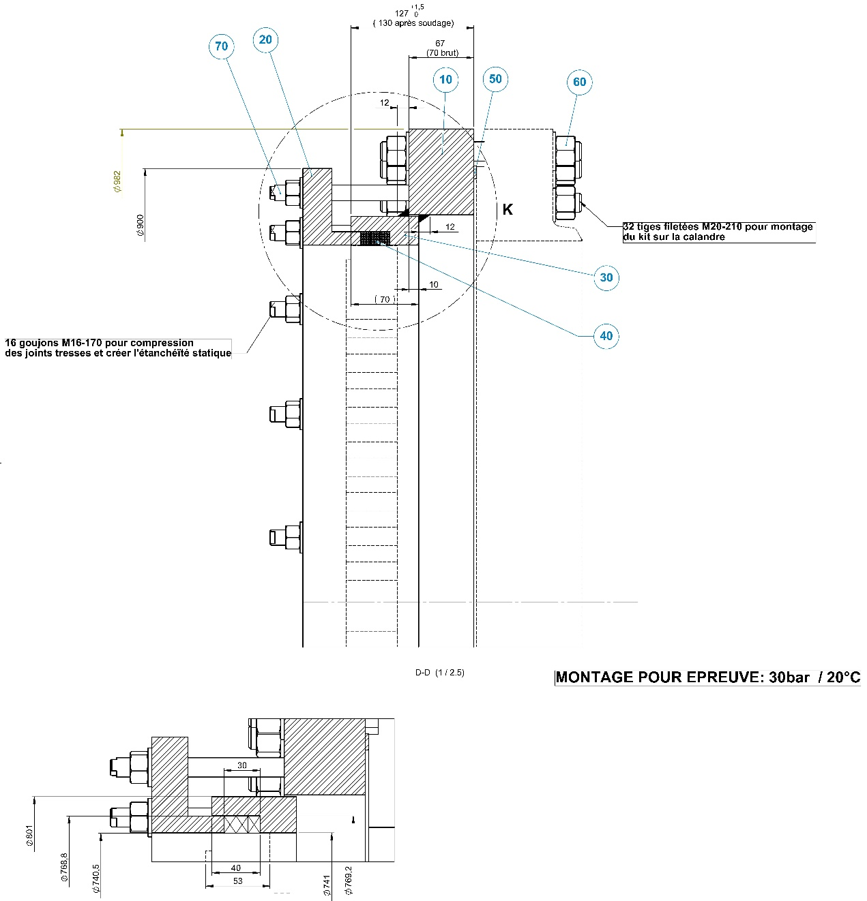

Heat Exchanger Test Ring Spare Parts Quiri

You may want to review shell and tube heat exchanger inspection procedure and related inspection and test plan.

. Wholesale Test Ring For Heat Exchanger Find 30 test ring for heat exchanger products from 18 manufacturers suppliers at EC21. Both are water source heat-pump loops both heat exchangers are approx 6 years old. Test rings allow the owneruser of a shell and tube heat exchanger to hydrotest the tube bundle while its outside of the exchanger.

Heat Exchangers are pieces of process equipment built and designed for maximum efficiency of heat transfer between two different machines or mediums. The test ring 26 is in the form of an annulus having a rabbet 28 formed to receive the hook bolts 18 and the tube sheet 13 in the same manner as the floating head receives the same tube sheet 13. 04012009 1209 AM.

Exchangers have been given a variety of names depending on their heat transfer functions. Liquid dye red or fluorescent dye is sprayed over an area of the heat exchanger expected of leakage and the interior is inspected for evidence of the dye. By the use of this test ring pressure can be applied on the shell side of the exchanger and the tube joints in the tube sheet may be then easily inspected for leakage since the ends thereof.

The shell-and-tube heat exchanger is by far the most common type of heat exchanger used in industry. Test rings allow the owneruser of a shell and tube heat exchanger to hydrotest the tube bundle while its outside of the exchanger. A test head assembly for heat exchanger tube bundles consists of a structural frame to support the bundle test heads sealing devices between the test heads and the tube sheets clamps securing the test heads to the bundle with the sealing devices therebetween a supply reservoir for the test fluid a collection reservoir to receive the test fluids after testing to permit proper.

The test ring is necessary to carry out the ten-year hydraulic test in the presence of the authorized inspector. Sorry we have detected unusual traffic from your network. The one common characteristic is the separation of the cold liquid stream from the hot liquid stream by a barrier.

This is ordinarily accomplished by placing a split ring flange behind the tubesheet and bolting a head or a flat cover up to it with some sort of gasket usually an o-ring placed in between-Christine. A floating head type heat exchanger is a type of shell and tube heat exchanger in which the tube sheet assembly is free and free to move within the shell or shell cover. Please slide to verify help help.

Test ring for heat exchanger. ANSON can manufacturer various kinds of floating head heat exchangers accordance with the TEMA API660. This exchanger is widely used for the service where the temperature is high between the shell and tube bundle that creates expansion issues.

ANSON can manufacturer various kinds of floating head heat exchangers. Champion Trading Corporation pressure testing Stainless Steel shell and tube heat exchanger by American Standard at its New Jersey facility. In most industrial processes the loss of heat is very.

This device is an indispensable tool for checking the tightness of the tube connection on the floating tube plate. Heat exchangers come in a variety of designs ie. Out of all different types shell and tube heat exchangers are quite popular and widely used for a variety of applications.

FLOATING HEAD Heat Exchanger General Assembly view Shell side Inlet Shell side Outlet Tube side Inlet Tube side Outlet Shell Back Cover Distributor Tube Sheet Gaskets Gasket Saddle Floating Head Bundle Floating Head Heat Exchanger Cross Sectional View Baffle Shell Distributor Back cover Tube Bundle Floating Head Split ring FLOATING HEAD Heat Exchanger. Plate Fin Type Exchangers. These names serve to identify the heat transfer function of the hardware and in many cases also conjure up the image.

The floating head type heat exchanger is a type of shell and tube heat exchanger in which the tube sheet assembly is independent and free to move within the shell or the shell cover. The Heat Exchanger Inspection article provides you with information about the inspection of the heat exchanger and heat exchanger testing during the manufacturing phase as well as in-service inspection in operating units. You mean Test Ring would act as a loose type flange during hydrotesting and it should be designed accordingly no matter if the channel head flange is integral type.

Heat exchanger test using a penetrating dye such as Magna Flux. These exchangers are widely used for the service where the temperature between the shell and the tube bundle is high which creates expansion issues. Design pressures range from full vacuum to 6000 psi.

Much of the equipment used in the refining and processing industries is known as Process Equipment. Its channel head flange is integral type. Heat Exchanger Test Rig.

13 This Standard is applied to heat exchangers designed beginning with. The general principles of the mechanical design of the following types of exchangers are given in the Heat Exchanger Design Handbook 1994 and full descriptions of each are given under the corresponding entries in this encyclopedia. Kettle reboiler condenser thermosiphon reboiler regenerator recuperator blow-down heat exchanger heating element and so on.

Shell tube heat exchangers. 12 For purposes of this Standard the designation shell-and-tube heat exchanger covers heat exchangers in general and heaters coolers reboilers and other shell-and-tube heat exchanging equipment. Lets look at a typical shell tube heat exchanger diagram to understand its structure.

Coil shell plate shell tube etc. A heat exchanger is the mechanical device used to contact two fluids in a controlled manner. Items test flange and test ring customised as per drawing application heat exchanger material grade - sa-266 gr4 of asme sec-ii part-a ed-2019 1.

Well the exchanger is TEMA type - BHU. Different types of heat transfer equipment is widely used in the process industry to heat up or cool down process fluids. Shell and Tube Exchangers.

If using a fluorescent dye the heat exchanger is examined using a UV or black light. Generally there are four basic types of floating head heat exchanger outside packed stuffing box TEMA P outside packed lantern ring TEMA W the floating head with backing device TEMA S and pull through TEMA T designs. Choose quality test ring for heat exchanger manufacturers suppliers exporters now - EC21.

General requirements as per sa-788 of asme sec-ii part-a ed-2019-. Heat exchanger test ring drawing Purity encouraged nail artwork with white heart shapes on the nail strategies straightforward but exquisite. This hydraulic test ring was manufactured by Quiri for a tubular heat exchanger with floating head type TEMA AES.

It can be fabricated from a wide range of materials both metallic and non-metallic. 1 heat exchanger is piped with the boiler water flowing thru the shell and it has more than enough capacity.

Piston Type Differential Pressure Gauge Principle Pressure Gauge Pistons Pressure

Pressure Relief Valve Internal Elements Nomenclature Chemical Engineering Relief Valve Engineering

Macarthy Gin Cotton Plant Roller Bar Cotton

Fulton Boiler Schematic Fulton Boiler Wiring Diagram Oil Steam Boiler Boiler Heating Boilers

C500 Shell Tube Heat Exchanger Xylem Jamaica

Bn Ds T13 Typical Construction Details For Test Rings Of Floating Head Type Exchangers

Components Of The Heat Exchanger As Arranged On The Top Of The Soil Download Scientific Diagram

Bn Ds T13 Typical Construction Details For Test Rings Of Floating Head Type Exchangers

0 comments

Post a Comment